Inventory Management is one of the key principles of management. Efficient e-commerce inventory management is crucial to the success of any business, regardless of size or industry.

While inventories are a must-have, it takes a while to hack inventory management. Business owners know the challenges of keeping track of products, shipping, sales, orders, etc.

Without proper inventory management, you may run into setbacks that can hinder the overall progress of your business.

To avoid these issues, we’ll discuss the best tips for efficient inventory management. These tips will help you make informed decisions about your inventory and streamline your processes.

Let’s explore.

Tips for Efficient e-commerce Inventory Management

Inventory management simply means taking care of your products and inventories, ensuring you have the right product in stock in the right quantity. This ensures you prevent stock-out, minimize cost and improve customer satisfaction.

Below are some of our Tips for adequate inventory management in your e-commerce business:

1. Prioritize Your Inventory with ABC Analysis

To effectively manage your inventory, plan and organize inventories based on important factors. Relevant factors include product demand, value of the product, profit margin etc. This will guide you to sufficiently stock high-demand items.

To categorize items based on values and importance, there are certain ways to achieve it. For this guide, we will discuss its implementation with the ABC Analysis method.

How does ABC Analysis work?

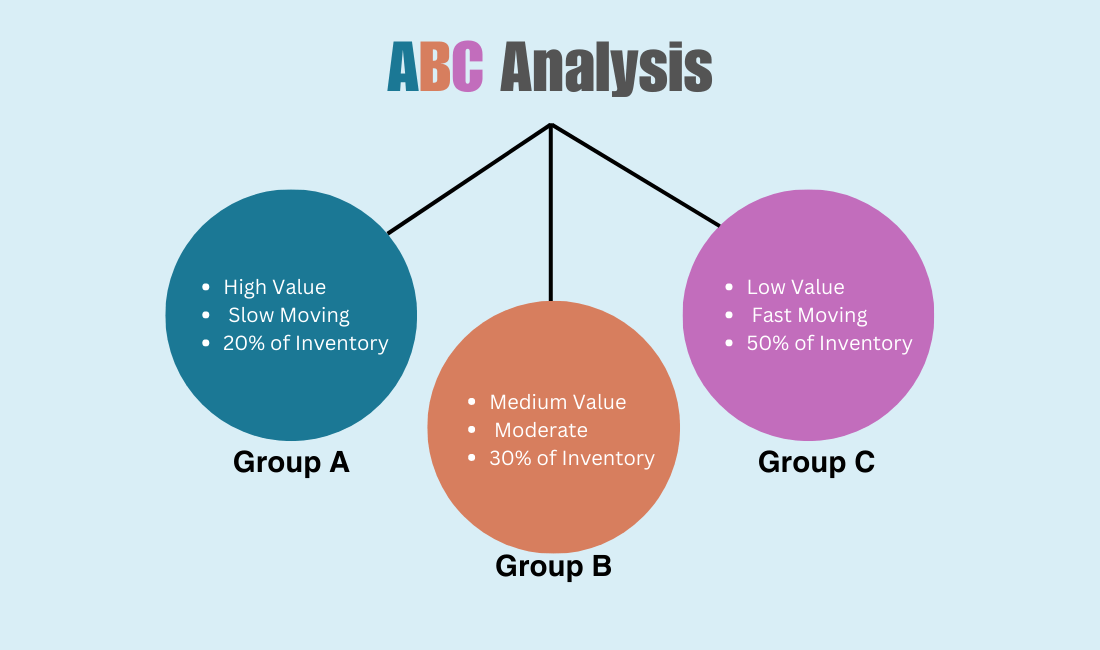

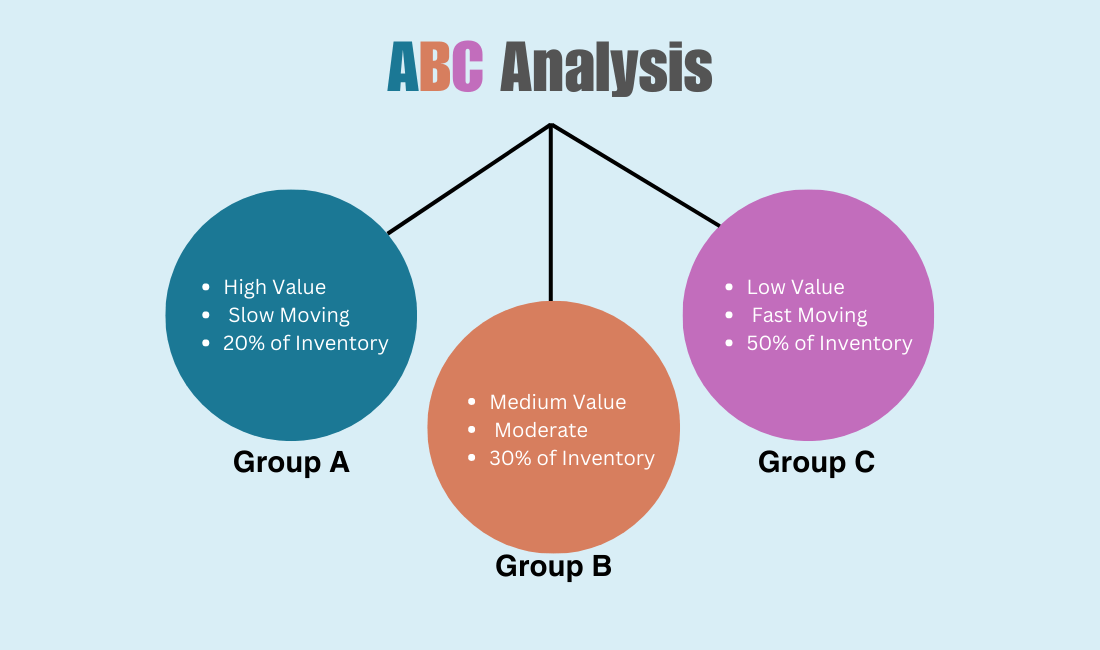

Items are shared into Groups A, B and C with

Group A – Items with the highest value in terms of annual consumption, though they amount to 10-20% of the total inventory account for 80% of the company’s profit. It is important to prioritize these items.

Group B – Moderate-value products with moderate demand. They sell faster than Group A but slower than Group C.

Group C – Items with the lowest value consumption rate, fast-moving products that account for 5% of the company’s profit and amount to 50% of the overall inventory.

2. Conduct Regular Inventory Audits

Inventory audits mean taking physical records of your stock and comparing them with your digital records. These management practices help to identify any discrepancies or errors and provide insight into your inventory turnover rate.

This audit can be done on a daily, weekly, monthly or quarterly basis, depending on the business and its policy. However, regular inventory audits encourage accurate tracking and forecasting.

3. Optimize Demand Forecasting

Use sales data, market trends and customer behaviors to predict future demands. This helps you to focus on the inventories that are more profitable and are likely to be in demand in the future.

In addition, data will enable you to adjust your inventory levels and order quantities.

4. Establish Supplier Relationships and Monitor their Performance

Suppliers play an important role in inventory management.

Be deliberate about working with reliable and trustworthy suppliers so you can communicate your expectations regarding the lead periods, order frequencies, and quality standards. A great relationship with them guarantees excellent delivery when you beckon.

Also, building strong partnerships with your suppliers can help you to negotiate better prices, faster delivery and reliable inventory availability.

Discover 10 AI Tools for e-commerce

While at it, keep track of the supplier’s performance on quality, time and resources. Communicate when you notice discrepancies in delivery or compromises on quality.

Ensure to have other suppliers you can switch to when your most reliable supplier cannot deliver within the stipulated time to avoid the risk of stock-out.

5. Set a Reorder Point and Safety Stock Levels

A reorder point is the level at which your inventory will be replenished. As a business owner, waiting until inventory is finished will strain your inventory management and sales.

How do you determine Reorder Point?

Multiply your daily unit sales (daily number of items sold) by the Lead time (the day order was requested to the delivery date), and add the safety stock level.

The safety stock is the amount of safe inventory set-asides for the contingencies such as a sudden surge in demand or delayed supplier. It also helps prevent stock-out in case of delayed supply.

6. Implement a Just-in-Time(JIT) Approach

Implementing a JIT inventory approach ensures you have just the right amount of inventories to be delivered. This is beneficial to businesses with little to no storage facility looking to improve productivity.

Some benefits of JIT include:

- Reduced Cost and Wastage: It eliminates the need for storage space, excessive inventory and extra overhead and operational costs. Also, it reduces the risk of unsold inventories and other defects on products due to improper storage or handling.

- Increase in Productivity: Time and resources spent on manufacturing and product parking are reduced significantly with JIT. It also reduces the cost of production thereby increasing productivity.

- Improved Quality: When fewer products are moving on the floor, it makes quality inspection more efficient and effective. Also, defects in goods can be easily identified and resolved.

7. Optimize Warehouse Layout and Organization

Efficient warehouse layout and organization enhance order fulfillment speed and accuracy. Use efficient storage systems like bin locations, barcodes, and RFID tags to facilitate easy tracking and retrieval of products. Arrange your inventory strategically, grouping similar items, and ensure clear labeling for quick identification.

8. Track Sales and Monitor Key Performance Indicators (KPIs)

Sales tracking helps you to identify inventories with low-turnover or unsold inventories and make better decisions about your inventory management.

Likewise, monitor KPIs related to inventory management to gauge your performance and identify areas for improvement. Some key metrics include inventory ratio, fill rates, backorder rates, order accuracy and carrying cost. Regular reviews of these metrics help you make data-driven decisions and optimize your inventory processes.

9. Utilize Inventory Management Software

Just like every other part of management, some software are available for inventory management. For efficiency, it is crucial to streamline your inventory processes with inventory management software. Through automation, this software helps to make your inventory processes and operations smooth and effective.

These tools can track stock levels, generate reports, set reorder points and even integrate your e-commerce platform for real-time updates. Such software provides efficiency and reduces human error.

10. Integrate Management Tools

Asides inventory software tools, you can use other technological tools to streamline your processes. Tools such as Mobile Scanners and Point of Sale (POS) systems improve your inventory management.

Conclusion

Efficient e-commerce inventory management is crucial for every business in maintaining its stock levels, minimizing costs and meeting customers’ expectations.

By implementing these ten tips, you can streamline your inventory management and drive success in your e-commerce business.